Share & grow the world's knowledge!

We want to connect the people who have knowledge to the people who need it, to bring together people with different perspectives so they can understand each other better, and to empower everyone to share their knowledge.

Create A New AccountLatest News & Updates

Discy Latest Articles

How to pour silicone compound mold ring parts

The ring part refers to the part with most hollow structure in the middle and the material part is closed. In some assembled products, there are more ring parts. It also represents a large type of part in the complex ...

What methods can be used to process gear prototype parts

Gear parts are needed in some products. In order to design gears, prototypes of gear parts are generally required. Then, what methods can be used to process gear prototype parts? The following 3d-printing-china.com is here to introduce you. 1. Cnc ...

Common Problems And Solutions Of FDM 3D Printing Products

3D printing enthusiasts often encounter some problems when using FDM 3d printing machine. Today we will take inventory, analyze the reasons and provide solutions. 01 Model drawing When the nozzle is empty, the middle path does not need to extrude ...

CNC precision machining should pay attention to technical operation and maintenance

At present, in the process of controlling different processing technologies, computers can play a very important role, and some tools for numerical control technology, or some mutual mold selection and design are very important, the introduction of CNC precision ...

What are the types of cnc parts processing and how to do a good job clamping workpiece?

When starting medical machining, the operator should adjust the feed speed to a very small value, execute in a single block, concentrate on positioning, dropping the tool, and inserting the tool quickly. Put the hand on the stop button and stop immediately if there is a problem, pay attention to the direction of the tool movement. To ensure safe feed, then slowly increase the feed speed to a suitable level, and at the same time add coolant or cold air to the tool and the workpiece. (more…)

The diversity of CNC prototype model processing methods?

The diversity of CNC prototype model processing methods?

Do you know the CNC prototype model? The following Pingte precision hardware parts processors will explain to you!

With the gradual growth of the prototype industry, the manufacturing process has also been updated day by day. There are 3D printing and silica gel casting. But CNC machining is still the most common way to produce parts. At present, the common methods of CNC machining prototype models are as follows: (more…)

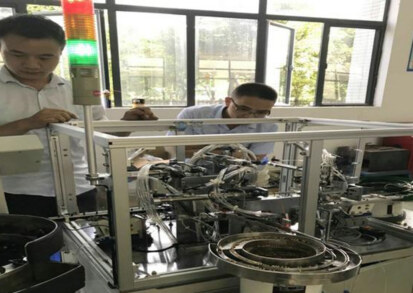

If you want to do a good job of non-standard design, these points must be mastered!

Non-standard parts refer to the special non-standard parts that the country does not have mass production, but various departments of the national economy do need special non-standard parts. (more…)

Key Technologies of CNC Machining Services for Cloud Manufacturing

With the in-depth development of information technology in the manufacturing industry towards networking, intelligence and service, the concept of cloud computing has been introduced into the manufacturing industry, resulting in the concept of cloud manufacturing. Cloud manufacturing is a new ...

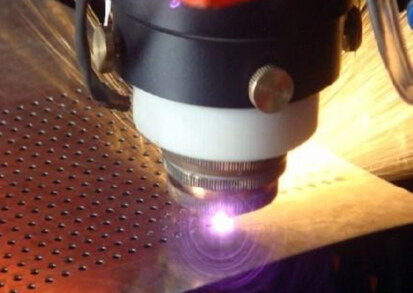

How is the quality of the cutting section of the metal laser cutting machine?

When understanding the types of cutting machines, the metal laser cutting machine has become a product with good results. In the process of grasping this product, people can understand that the quality of the cut section processed by the product ...

What are the characteristics and advantages of the new fiber laser cutting machine

At present, the newly developed fiber laser cutting machine equipment has great practical advantages in use, and has gradually become a more popular cutting equipment in the current processing market. The cutting process is a very basic process in sheet ...

What are the requirements for gravity casting cooling, why is there a problem of looseness?

The production and machining of many products require the process of gravity casting, and Dongguan gravity casting is a more commonly used casting process nowadays, but there is not a lot of learning about gravity casting. The following editor will ...

How to understand the sales price of laser cutting machine

Many users will inquire about the price of the laser cutting machine when purchasing the material-cutting laser cutting machine. The following is an analysis of the price of the laser cutting machine, because the technology now breaks the monopoly of ...

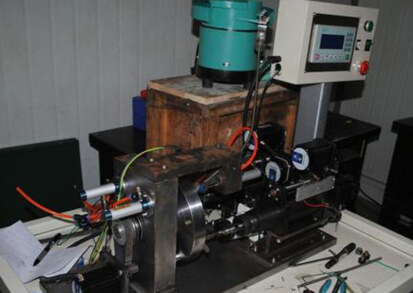

What are the main reasons for the instability of the tapping machine?

The tapping machine has high speed and high precision. It can detect the tapping with a tooth gauge and can run continuously at high speed. The motor is robust and can be automated. One person can operate multiple devices at ...

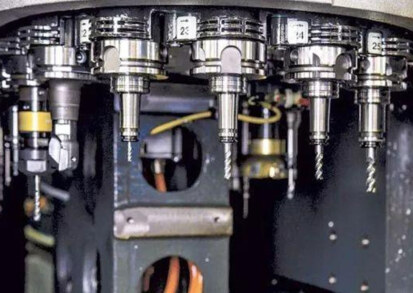

Matters needing attention when optimizing drilling and tapping center machines

Use drilling and tapping center machines for mold processing. If you want to achieve higher power and precision requirements and better appearance quality, you must choose from machine tool selection, tool holder selection, tool selection, processing plan, program generation, and ...

It can avoid the sticking of the glass engraving machine

In terms of name, the glass engraving machine is very similar to the engraving machine, but in fact there are many differences. From the functional point of view, there are some overlaps with the engraving machine, but generally speaking, the ...

Three major parts that need to be paid attention to when designing Taiwan-group gantry machining center

Taiqun gantry machining center is a kind of machine tool with a wide range of uses. It is a kind of equipment with a portal frame and a horizontal long bed. It can use multiple milling cutters to machine the ...

The working process and daily maintenance method of glass engraving machine

The glass engraving machine is a kind of CNC machine tool, which is mainly used in the fine processing and special-shaped cutting of various ultra-thin glass. With the development and demand of the electronic consumer market in the future, more ...

Analyze the different feeding methods of double-end grinder

The machining accuracy that can be achieved by the double-end surface grinder is the first choice for machining workpieces that require high parallelism, size, and surface roughness of the top and bottom of the machined parts. The big difference between ...

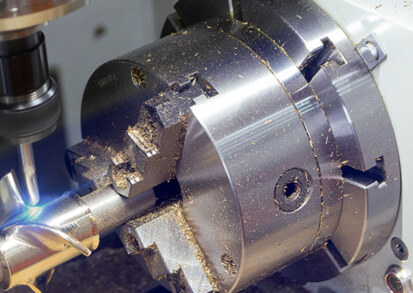

The advantages and precautions of the use of the two-jaw chuck for the rear pull oblique column

The two-jaw chuck of the back-drawn oblique column can upgrade the original equipment, optimize the traditional multi-clamping and multi-sequence processing mode to a single-clamping multi-sequence processing mode, improve the automation degree of the original equipment, and improve the processing accuracy ...

For the use of section steel cutting machines, users of these safety rules must remember to follow

The section steel cutting machine is a very powerful large-scale processing equipment, which can complete the cutting of the length of the section steel workpiece, the bevel of the web and wing plate, the wedge lock and the bolt hole ...

What problems should the machining center pay attention to when processing composite materials?

What problems should the machining center pay attention to when processing composite materials? In the processing of these composite materials, we have to process them according to the types of composite materials. Here is a brief introduction to some of ...

How to adjust the accuracy of CNC lathes is a very important thing

The CNC lathe is a precision lathe with high precision, high rigidity, high speed, high efficiency and high cost performance. Adopt horizontal flat guide rail structure, resin sand casting, good rigidity; guide rail quenching and fine grinding, precision and precision ...

What is the difference between precision stamping and ordinary stamping of CNC lathes

The precision stamping of a CNC lathe is essentially different from ordinary stamping. Precision stamping refers to various materials stamped out by a precision punching machine. These precision stamping parts themselves have higher precision requirements than ordinary stamping, such as ...

The Status Quo Of CNC Machine Tools In China And The Main Problems In The Development

In today’s world, industrially developed countries attach great importance to the machine tool industry, and are racing to develop advanced machine tools of mechatronics, high precision, high efficiency, and high automation in order to accelerate the development of industry and ...

The Essence Collection Of CNC Machining Programming Experience

The speed of the white steel knife should not be too fast. For coppersmiths, use white steel knives less frequently, and more use flying knives or alloy knives. When the workpiece is too high, you should use different length cutters ...

CNC Machining And Flexible Manufacturing

In 1946, the University of Pennsylvania in the United States successfully developed the world’s first electronic computer, which provided humans with tools that could enhance and partially replace mental labor, laying the foundation for the evolution of human society into ...

12 Experience Summaries Of CNC Machining

Due to the complexity of CNC machining (such as different machine tools, different materials, different tools, different cutting methods, different parameter settings, etc.), it is determined that CNC machining (whether machining or programming) reaches a certain level. It must take ...

Some Knowledge About The Use Of CNC Machining Carbide Tools

In addition to end mills and some end mills and cemented carbide as milling cutter materials for milling stainless steel, the other types of milling cutters are made of high-speed steel, especially tungsten-molybdenum series and high-vanadium high-speed steel, which have ...

Femtosecond Laser Technology For Medical Used

As a laser manufacturing company, we are often asked questions related to femtosecond laser surgery in ophthalmology. These questions typically involve the safety and precision of the surgery and the role we play as laser equipment providers. Next, let me ...

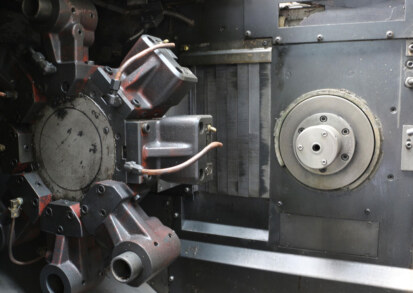

Basic Definition Of A Multi-Axis Machine

Multi-axis machining is a manufacturing process in which tools can be moved in 4 or more ways or directions to create parts that require precision machining, providing innovative and efficient solutions for complex geometric parts. This article will take a ...

Why Are Some Metal Parts Produced By Forging Rather Than Other Machining Methods?

First of all, we have to clarify what are the main metal CNC machining methods in current industrial production. Generally speaking, metal CNC machining methods are mainly divided into 4 categories: Casting: Metal Casting is the heating and melting of ...

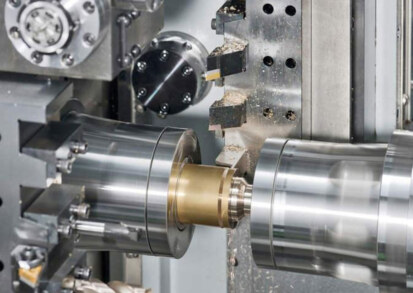

What are the selection criteria for CNC turning?

1. The CNC lathe can process complex workpieces such as straight cylinders, oblique cylinders, circular arcs and various threads, grooves, worms, etc. It has various compensation functions such as linear interpolation and circular interpolation, and is used in the mass production of complex parts. ARead more

- 1. The CNC lathe can process complex workpieces such as straight cylinders, oblique cylinders, circular arcs and various threads, grooves, worms, etc. It has various compensation functions such as linear interpolation and circular interpolation, and is used in the mass production of complex parts. A good economic effect.

- 2. Numerical control lathes and turning centers are high-precision and high-efficiency automated machine tools. Equipped with multi-station turret or power turret, it has a wide range of processing performance. The CNC machine tool automatically processes the processed parts according to the pre-programmed processing program.

- 3. The machining process route, process parameters, tool motion trajectory, displacement, cutting parameters (spindle rotation, feed, back tooling, etc.) of the part, and auxiliary functions (tool change, spindle forward rotation, reverse rotation, etc.) , Cutting fluid on, off, etc.), in accordance with the instruction code and program format specified by the CNC machine tool to write a processing program list, and then record the content of the program list on the control medium (such as punched paper tape, magnetic tape, magnetic disk, magnetic bubble Memory), and then input into the numerical control device of the numerical control machine tool, so as to direct the machine tool to process the parts.

- 4. This whole process from the analysis of the part drawing to the preparation of the control medium is called the compilation of the numerical control program. The difference between CNC machine tools and ordinary machine tools processing parts is that CNC machine tools automatically process parts according to the program, while ordinary machine tools must be operated by humans. As long as the program that controls the action of the machine tool is changed, the purpose of processing different parts can be achieved. CNC machine tools are especially suitable for processing small batches of parts with complex shapes and high precision requirements.

See lessWhat is CNC machining?

General CNC machining usually refers to precision machining, CNC machining lathe, CNC machining milling machine, CNC machining boring and milling machine, etc. 1. The feed processing route of the CNC lathe refers to the path that the turning tool moves from the tool setting point (or the fixed origiRead more

General CNC machining usually refers to precision machining, CNC machining lathe, CNC machining milling machine, CNC machining boring and milling machine, etc.

- 1. The feed processing route of the CNC lathe refers to the path that the turning tool moves from the tool setting point (or the fixed origin of the machine tool) until it returns to the point and ends the processing program, including the path of cutting processing and the cutting in and out of the tool, etc. Non-cutting idle travel path.

- 2. The feed route for finishing is basically carried out along the part contour sequence. The focus of determining the feed route is to determine the feed route for rough machining and idle stroke.

- 3. In CNC lathe processing, the determination of the processing route generally follows the following principles, which should ensure the accuracy and surface roughness of the workpiece to be processed.

- 4. Make the processing route the shortest, reduce the idle travel time, improve the processing efficiency, try to simplify the numerical calculation workload, simplify the processing procedure, and for some reusable procedures, subroutines should be used.

- 5. CNC index-controlled machine tools are programmed and controlled by CNC machining languages, usually G codes. The CNC machining G code language tells the Cartesian position coordinates of the machining tool of the CNC machine tool, and controls the feed speed and spindle speed of the tool, as well as the tool changer, coolant and other functions.

See lessHow to learn cnc machining

1. Be familiar with the various hardware of the CNC lathe you control, such as the spindle, tool magazine and related buttons. In terms of software, you must learn programming carefully and know each instruction well, because many of them need manual programming in actual processing. 2. Understand tRead more

Learn from practice and learn while processing. I believe you will make great progress.

See lessHow to calculate machining cost for cnc machines

You already know the main items of machining cost, In detail, each factory is different. Generally speaking, large companies have higher costs. Small and micro companies have lower costs. So small businesses and big companies are unwilling to do it. We do tooling molds, Also do sporadic processing sRead more

You already know the main items of machining cost,

In detail, each factory is different.

Generally speaking, large companies have higher costs.

Small and micro companies have lower costs.

So small businesses and big companies are unwilling to do it.

We do tooling molds,

Also do sporadic processing such as small quantities and single pieces.

The main ones are material costs, processing fees, taxes, transportation fees, management fees and profits. The material cost is the weight of the part blanking multiplied by the price of the material is the material cost. The processing cost needs to calculate the man-hours of each process, and then there are different labor prices according to different regions and types of work. Generally, general lathes, milling machines, etc. are 60-80 yuan/hour, wire cutting fast wire is 0.004-0.006 yuan/square millimeter, small machining center 80-100 yuan/hour······

See lessHow much does cnc machining cost

Hello, if the finish requirements are not high, and the hole spacing accuracy requirements are not particularly high, you can choose CNC milling machine and CNC drilling machine to complete; as for the tool, milling six faces, generally use end milling cutter; drilling D11 The hole can be made of alRead more

Hello, if the finish requirements are not high, and the hole spacing accuracy requirements are not particularly high, you can choose CNC milling machine and CNC drilling machine to complete; as for the tool, milling six faces, generally use end milling cutter; drilling D11 The hole can be made of alloy spiral tungsten steel drill bit, which is processed by G83 method, in order to arrange cutting and better ensure the Ra value measured in the hole. . . . . . . . . . . . Positive answer to this building

See lesshow to choose a right spindle for cnc machining

C stands for lathe, K stands for numerical control, 6 stands for horizontal, 1 stands for ordinary, and 32 stands for 1/10 of the maximum diameter of the spindle rotation, which is the maximum workpiece diameter that can be processed. Connected: Ordinary horizontal CNC lathe with a rotating diameterRead more

C stands for lathe, K stands for numerical control, 6 stands for horizontal, 1 stands for ordinary, and 32 stands for 1/10 of the maximum diameter of the spindle rotation, which is the maximum workpiece diameter that can be processed. Connected: Ordinary horizontal CNC lathe with a rotating diameter of 320mm. Horizontal lathes are represented by C6×××, where C——machine tool classification number, which means lathe type machine tools; 6——group system code, which means horizontal type. Others indicate the relevant parameters and improvement numbers of the lathe. Horizontal lathe is a machine tool that mainly uses a turning tool to turn a rotating workpiece. Drills, reamers, reamers, taps, dies and knurling tools can also be used on the lathe for corresponding processing.

The machine tool spindle refers to the axis that drives the workpiece or tool to rotate on the machine tool. The main shaft components are usually composed of main shaft, bearings and transmission parts (gears or pulleys). Choose the 6132 lathe spindle for accurate and professional quality assurance; the spindle is the most common part of the machine, mainly composed of inner and outer cylindrical threaded splines and transverse holes. The function of the spindle is the executive part of the lathe, and it mainly supports the transmission part. In addition to the transmission torque, it drives the workpiece to directly participate in the surface forming movement during work. At the same time, the spindle also ensures that the workpiece has the correct relative position to other parts of the lathe.

Main functions of lathe spindle:

Model 6132 CNC lathe adopts mechatronics design, beautiful appearance, reasonable structure, wide range of uses and convenient operation. The bed guide rail adopts super-audio frequency rice quenching technology, which has strong wear resistance and good accuracy retention; the spindle system has advanced structure, high rotation accuracy, good vibration resistance, and high cutting performance; vertical and horizontal use ball screw transmission ; Excellent dynamic response, low noise of the whole machine. The 6132 lathe spindle is accurate. This machine tool has strong adaptability for the rotation processing of large, medium and small batches, multiple varieties and multiple specifications, especially for processing special parts such as conical and spherical surfaces. It can show its efficiency. The superiority of high, stable and reliable quality.

1. Electric tool rest

It adopts worm gear and screw drive, and the working principle of advanced three-tooth disc meshing screw locking. Automatic indexing and tool change are controlled by the CNC system. The tool post has a fast indexing speed and high indexing accuracy, and the repetitive accuracy of the tool post is less than or equal to 0.005mm.

2. Centralized lubricating oil pump

The centralized manual lubricating oil pump can be used to achieve automatic lubrication, and the lubrication can be carried out at regular and quantitative intervals to ensure the smooth and good movement of various parts, and greatly improve the accuracy and service life of the machine tool.

3. Precision ball screw pair

The machine tool adopts high-precision ball screw with transmission efficiency as high as 85-95%, which is 2-4 times that of traditional screw. The transmission has no backlash, no vibration, and no crawling phenomenon at low speed. The machine tool has the characteristics of high positioning accuracy and high repeat positioning accuracy. The screw rod is directly connected with the feed motor, which has high reliability and guarantees the accuracy of the machine tool.

CNC6132 CNC lathe is an economical CNC lathe with exquisite design, equipped with a highly reliable CNC system. The bed guide rail is made of wear-resistant cast iron, and the saddle and slide plate are pasted with plastic. The feed transmission adopts a ball screw pair, and the appearance is fully enclosed and protected. The CNC6132 CNC lathe is driven by a servo main motor and has an independent main shaft structure, which can realize the stepless speed regulation of the main shaft. Realize two-axis control, can automatically complete the processing of inner and outer cylindrical surfaces, arbitrary conical surfaces, arc surfaces, end surfaces, and metric and inch threads. It is suitable for the processing of shafts and disc sleeve parts of multi-variety, small and medium-sized products. The processing of complex and high-precision parts can even show its superiority. The machine tool adopts mechatronics design and adopts four-tool automatic rotary tool post. It is easy to operate and efficient. Through programming, it can automatically complete internal and external cylindrical surfaces, conical surfaces, arc surfaces, and threads for various disk and shaft parts. It can perform cutting, grooving, drilling, reaming, etc.

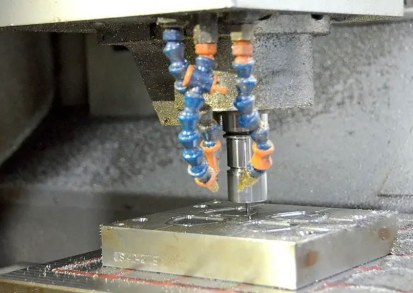

See lesswhat is cnc milling

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical head and multiple flutes is usually called an end mill or an end mill. It can move along different axes and is used to machine long and narrow spaces, grooves, and outerRead more

CNC milling or manual milling is a machining process used to process prismatic parts. A milling cutter with a rotating cylindrical head and multiple flutes is usually called an end mill or an end mill. It can move along different axes and is used to machine long and narrow spaces, grooves, and outer contours. The machine tool for milling is called a milling machine, and the CNC milling machine is usually an exponential control machining center. Milling processing includes manual milling and CNC milling, and milling processing is carried out in the machining workshop.

See less