The production and machining of many products require the process of gravity casting, and Dongguan gravity casting is a more commonly used casting process nowadays, but there is not a lot of learning about gravity casting. The following editor will let everyone pass To understand the content of two aspects:

Why does gravity sand casting have certain requirements for cooling? This is because the mold temperature is required in the process of gravity casting in Dongguan, so this result can be achieved. Its cooling includes natural cooling and forced cooling. It can also be based on different conditions and requirements. To make a choice. There are two methods of forced cooling in gravity casting cooling, which should be compressed air cooling and water cooling. If compressed air is used for cooling, the air should also be evenly blown on the surface of the mold. There must be no missing places, otherwise it will affect the service life of the mold, or some other problems such as cracks, deformation, etc. will appear.

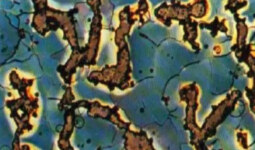

The reason for the formation of the porosity of the gravity casting is the same as that of the Dongguan gravity casting. If there is a problem of porosity, then there may be several reasons: 1. The casting shrinks during the casting process. , But did not replenish the molten metal in time. 2. The cross-section size of the mold or the incorrect position of the inner runner will cause some problems such as local overheating.