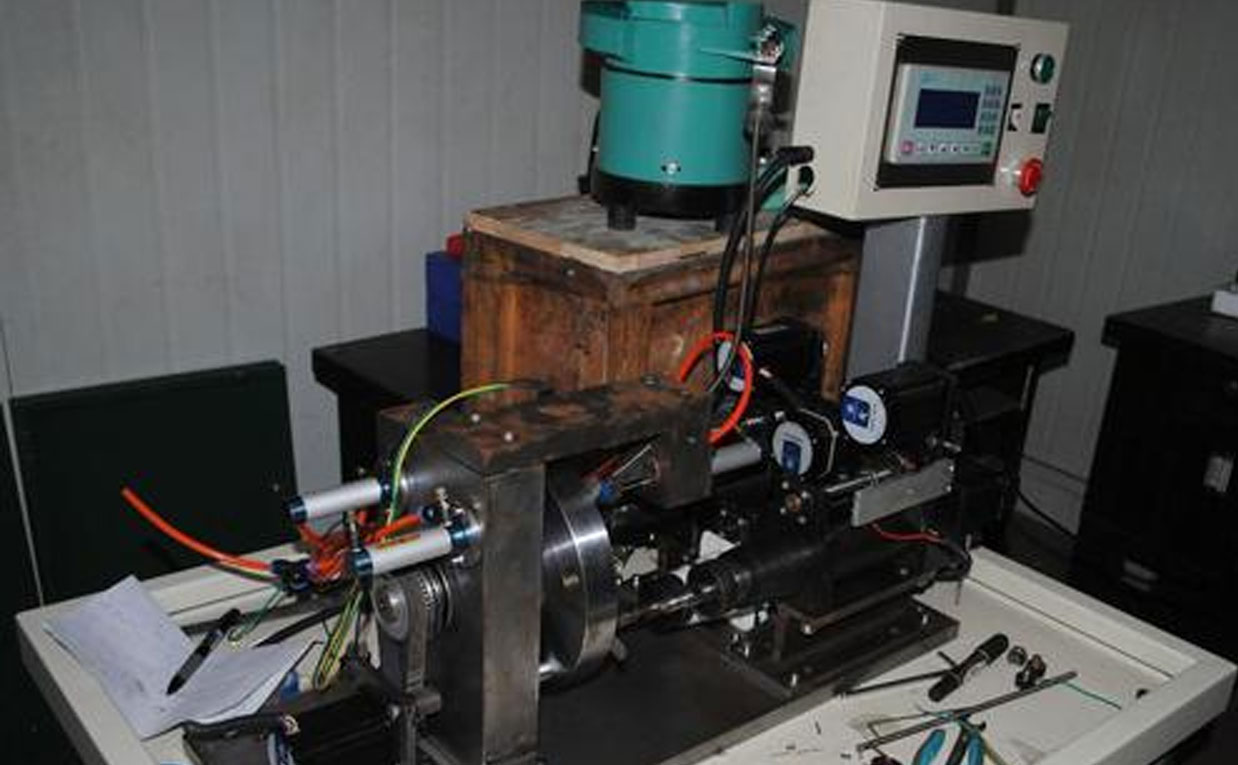

The tapping machine has high speed and high precision. It can detect the tapping with a tooth gauge and can run continuously at high speed. The motor is robust and can be automated. One person can operate multiple devices at the same time, which can greatly save labor costs. The high-precision tapping stroke adjustment is simple, the automatic reversing device can freely adjust the tapping stroke, and the shallow hole and the low cnc machining parts with holes can also be easily adjusted. Double safety devices can prevent damage to the tap. The main shaft can rotate up and down, and a double safety clutch is set for the forward and backward tools. The main shaft can automatically stop, even if the tool is reversed and retracted, the tool will not be damaged.

The pitch A and B gears of the tapping machine are completely matched with the A and B rotating shafts and the main shaft according to the pitch. Vertical stability, accuracy and precision are extremely high. When the screws are tightened, it can run freely without any effort. At the same time, it depends on excellent processed products, does not cause different lines of different thicknesses, and can develop perfect lines for soft products such as thin plates, light alloy metals and synthetic resins. It can also be equipped with a multi-axis machine for multi-axis simultaneous cnc operating, which greatly improves production efficiency.

So, what are the main reasons for the instability of the tapping machine?

- The tapping head is worn out or the tension spring is loose. Should check whether the tapping head is worn and the force is uneven, and then check whether the tension spring is too loose or replaced with a new spring.

- The adjustment of the tapping belt is not tight enough or the belt is damaged, resulting in slipping. If the V-belt is too loose, you can adjust the adjusting screw on the back of the machine to a proper state, or replace with a new belt.

- The tapping belt is too loose. Loosen the four small screws, then press down and tighten them. Four screws.

- The brake power of the clutch is poor, and the brake pads can be replaced or replaced.

- The micro switch is damaged, please replace it with a new one.

- The direction of the cam stop switch is wrong. If the startup is too slow, it will cause instability.

- The data is deformed or too much remains in the chuck. More information should be checked and more chucks organized.