Gear parts are needed in some products. In order to design gears, prototypes of gear parts are generally required. Then, what methods can be used to process gear prototype parts? The following 3d-printing-china.com is here to introduce you.

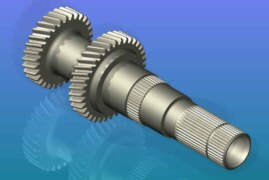

1. Cnc Machining

The hand plate of the gear parts is processed by cnc. Generally, it can be made of POM material. POM material is also called Saigang. This material is suitable for some parts that require greater hardness and better lubricity.

The hand plate model made of POM material has good performance. The reason why the gear-shaped hand plate model can be made is because it has good mechanical properties, flexible rotation, not easy to break, easy to process and shape, not easy to deform, wear-resistant and good lubrication performance.

2 3D Printing

For some parts used in the prototype of the prototype, the mechanical performance of the gear is not very high, and it does not carry a load, but only plays a role of simple transmission, and 3D printing 304 stainless steel gear prototypes and resin prototypes can be used.

The gear adopts 3D printing and can use high-toughness resin materials and nylon materials. The toughness resin has strong toughness and strength, and the surface is smooth. The toughness and strength of the nylon material is better than that of the tough resin, but the surface is frosted, and the thinnest is 0.8mm.

Because 3D printing has requirements for model wall thickness, generally gears with small modulus cannot be 3D printed, and the teeth are not clearly printed. Generally, the thinnest printing size of tough resin is 0.5mm, and the thinnest of nylon is 0.8mm.

The above is the analysis of what methods can be used to process the gear prototype model parts introduced by 3D-printing-china.com 3D printing service, and I hope to provide you with a reference.