Taiqun gantry machining center is a kind of machine tool with a wide range of uses. It is a kind of equipment with a portal frame and a horizontal long bed. It can use multiple milling cutters to machine the surface at the same time. The machining accuracy and production efficiency are relatively high. It is suitable for In batch and mass production, it can process the plane and inclined surface of large workpieces, and can also process space curved surfaces and some special parts. It is mainly used for the processing of various more complex plane, surface and shell parts, such as the milling processing of various cams, molds, connecting rods, blades, propellers and boxes. It can also be drilled, expanded, and countersinked. , Reaming, tapping, boring and other processing.

The three major parts of the design of the Taiwan Group Longmen Machining Center:

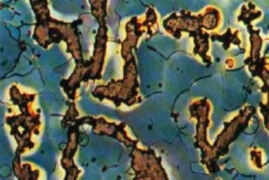

- 1. Equipment foundation: Its operation accuracy is closely related to the structural rigidity of the equipment foundation. Poor foundation construction and deformation after being loaded will seriously damage the accuracy of the machine tool. It is necessary to consider soil conditions and temperature changes to prepare the equipment foundation. Due to the influence of groundwater, etc., the equipment foundation should be constructed according to the foundation plan. The depth of excavation depends on the bearing capacity of the soil, and the rule of the foundation map is the depth. The root surface should be flat, and the equipment planing and milling machine must be carried out after the concrete has completely dried.

- 2. Equipment orientation: In order to maintain the operating accuracy of the machine tool, the equipment orientation should be selected with less impact, vibration and temperature changes, which is convenient for the lifting and transportation of parts and the place where traffic is not hindered. To prevent rapid wear and tear on the guide rail surface, the equipment orientation of the electrical cabinet on the foundation drawing is for reference only, and the user can make a decision according to the detailed layout of the workshop.

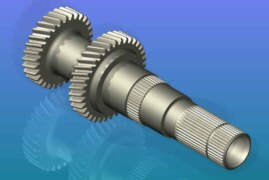

- 3. Machining center: It has five elements of CNC system, testing equipment, drive equipment, machine tool transmission chain, servo motor, with tool magazine and automatic tool change equipment. It combines the functions of CNC milling machine, CNC boring machine, and CNC drilling machine. It has powerful functions. In recent years, many turning machining centers have appeared, which can almost complete all the machining processes of rotating parts.