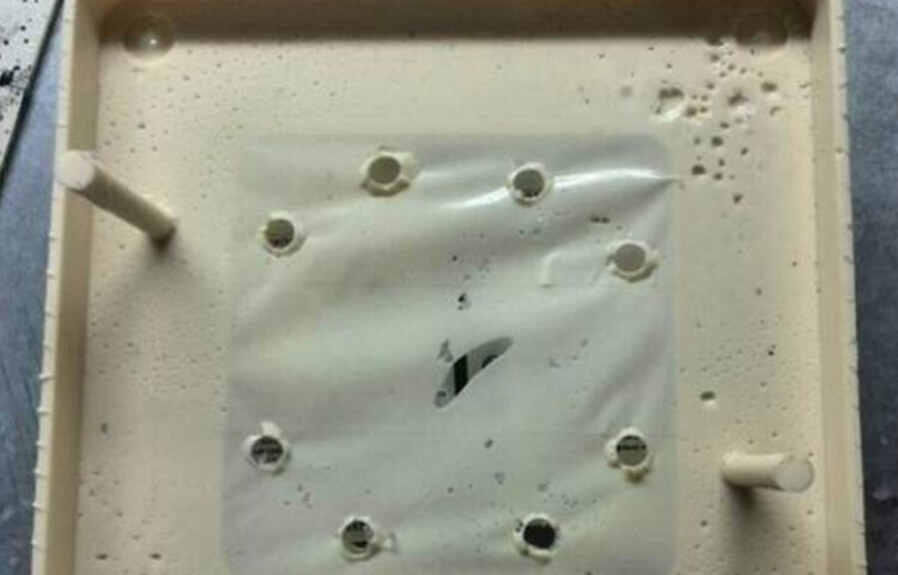

The ring part refers to the part with most hollow structure in the middle and the material part is closed. In some assembled products, there are more ring parts. It also represents a large type of part in the complex mold. During the casting of the ring part Bubbles and other problems often occur, so how to pour the silicone compound ring parts? Let me introduce to you.

Air bubbles appear in the ring part because the nozzles are not opened on the same parallel line and the lead groove is not cut, resulting in different flow and velocity of the upper and lower liquids, and this will cause the upper and lower parts of the part to be inaccurate in size .

Furthermore, because the nozzles are not on the same parallel line, the air bubbles are concentrated in the lower left corner and upper right corner of the piece when the material liquid flows.

How to pour it?

1 Change on the original mold

The first point: divide the lead trough in the middle of the original mold so that the material can flow more evenly and quickly to each part of the part and increase the space for accommodating air bubbles to reduce air bubbles!

The second point: add air holes near the lower left and upper right corners of the original mold to make the exhaust faster!

2 Remake the mold

The first point: No matter where the nozzle is opened, it must be parallel to make the bubble and the material liquid velocity more uniform, so that the bubbles can be better discharged from the pores around the mold to achieve the most reasonable use of the pores.

The second point: cut out the lead trough so that the material can flow to every position of the piece more quickly

The third point: The nozzle is best to be at the bottom of the film, and then use oblique pouring instead of flat pouring, which can make the size of the piece more accurate. Of course, it is better to press a piece of iron on the mold when pouring, so that it can also be used. The size of the piece is more refined!

The above is the analysis on how to pour the silicone compound ring parts introduced by 3D-printing-china.com 3D printing service. I hope to provide you with a reference.