I want to learn something to find a job, but I don’t know anything. My friend suggested to learn CNC milling. But I don’t even know what CNC milling is, so I want to collect information here. I want to ...

Discy Latest Questions

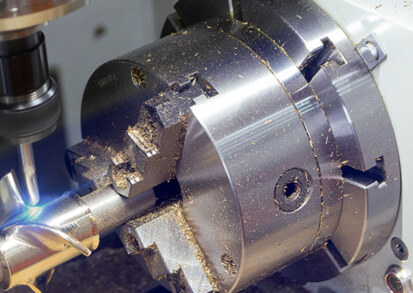

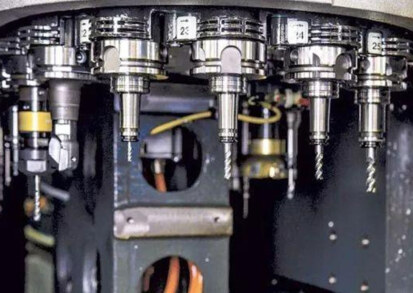

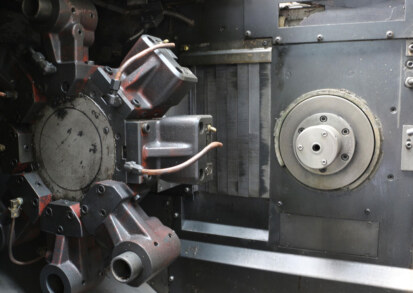

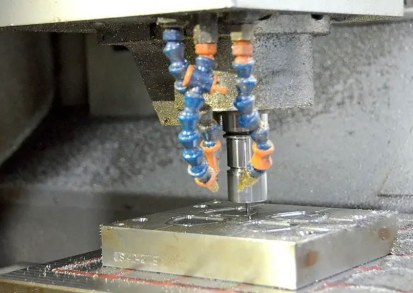

CNC machine spindle is a kind of spindle that can be processed at high speed. It is widely used in some small and medium-sized CNC machine equipment. It can be mainly used for high-speed processing, drilling and milling, punching, etc. ...

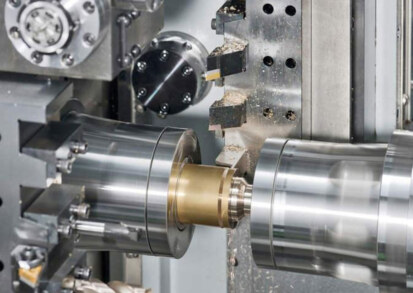

Material 45# steel, length 592 width 300 thickness 41.2 processing two upper and lower planes, four sides, plus 16 holes of 11, the finish is not required, if the processing center is charged at 100 yuan per hour, this processed ...

Does the tool compensation need to be added a little bit during the machining process? Can it be reduced; what tools are needed 80 lower for machining

I know that all of these have to be counted, equipment depreciation, tool costs, electricity bills, cutting fluid, rail oil, hydraulic oil, wages, workshop tools, but how to calculate each of these? Teachers, please answer me carefully

The essence of pressure casting (referred to as die casting) is to fill the die-casting cavity with liquid or semi-liquid metal at a higher speed under high pressure, and form and solidify under pressure to obtain castings. Die casting features ...

Is there a standard or model for CNC machining quotation, such as how to report according to the piece, how to report according to the working hours, and what the unit price is. Kindly explain it, I would be very ...