The ring part refers to the part with most hollow structure in the middle and the material part is closed. In some assembled products, there are more ring parts. It also represents a large type of part in the complex ...

Discy Latest Articles

What methods can be used to process gear prototype parts

Gear parts are needed in some products. In order to design gears, prototypes of gear parts are generally required. Then, what methods can be used to process gear prototype parts? The following 3d-printing-china.com is here to introduce you. 1. Cnc ...

Common Problems And Solutions Of FDM 3D Printing Products

3D printing enthusiasts often encounter some problems when using FDM 3d printing machine. Today we will take inventory, analyze the reasons and provide solutions. 01 Model drawing When the nozzle is empty, the middle path does not need to extrude ...

CNC precision machining should pay attention to technical operation and maintenance

At present, in the process of controlling different processing technologies, computers can play a very important role, and some tools for numerical control technology, or some mutual mold selection and design are very important, the introduction of CNC precision ...

What are the types of cnc parts processing and how to do a good job clamping workpiece?

When starting medical machining, the operator should adjust the feed speed to a very small value, execute in a single block, concentrate on positioning, dropping the tool, and inserting the tool quickly. Put the hand on the stop button and stop immediately if there is a problem, pay attention to the direction of the tool movement. To ensure safe feed, then slowly increase the feed speed to a suitable level, and at the same time add coolant or cold air to the tool and the workpiece. (more…)

The diversity of CNC prototype model processing methods?

The diversity of CNC prototype model processing methods?

Do you know the CNC prototype model? The following Pingte precision hardware parts processors will explain to you!

With the gradual growth of the prototype industry, the manufacturing process has also been updated day by day. There are 3D printing and silica gel casting. But CNC machining is still the most common way to produce parts. At present, the common methods of CNC machining prototype models are as follows: (more…)

If you want to do a good job of non-standard design, these points must be mastered!

Non-standard parts refer to the special non-standard parts that the country does not have mass production, but various departments of the national economy do need special non-standard parts. (more…)

Key Technologies of CNC Machining Services for Cloud Manufacturing

With the in-depth development of information technology in the manufacturing industry towards networking, intelligence and service, the concept of cloud computing has been introduced into the manufacturing industry, resulting in the concept of cloud manufacturing. Cloud manufacturing is a new ...

How is the quality of the cutting section of the metal laser cutting machine?

When understanding the types of cutting machines, the metal laser cutting machine has become a product with good results. In the process of grasping this product, people can understand that the quality of the cut section processed by the product ...

What are the characteristics and advantages of the new fiber laser cutting machine

At present, the newly developed fiber laser cutting machine equipment has great practical advantages in use, and has gradually become a more popular cutting equipment in the current processing market. The cutting process is a very basic process in sheet ...

What are the requirements for gravity casting cooling, why is there a problem of looseness?

The production and machining of many products require the process of gravity casting, and Dongguan gravity casting is a more commonly used casting process nowadays, but there is not a lot of learning about gravity casting. The following editor will ...

How to understand the sales price of laser cutting machine

Many users will inquire about the price of the laser cutting machine when purchasing the material-cutting laser cutting machine. The following is an analysis of the price of the laser cutting machine, because the technology now breaks the monopoly of ...

What are the main reasons for the instability of the tapping machine?

The tapping machine has high speed and high precision. It can detect the tapping with a tooth gauge and can run continuously at high speed. The motor is robust and can be automated. One person can operate multiple devices at ...

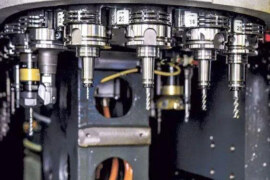

Matters needing attention when optimizing drilling and tapping center machines

Use drilling and tapping center machines for mold processing. If you want to achieve higher power and precision requirements and better appearance quality, you must choose from machine tool selection, tool holder selection, tool selection, processing plan, program generation, and ...

It can avoid the sticking of the glass engraving machine

In terms of name, the glass engraving machine is very similar to the engraving machine, but in fact there are many differences. From the functional point of view, there are some overlaps with the engraving machine, but generally speaking, the ...

Three major parts that need to be paid attention to when designing Taiwan-group gantry machining center

Taiqun gantry machining center is a kind of machine tool with a wide range of uses. It is a kind of equipment with a portal frame and a horizontal long bed. It can use multiple milling cutters to machine the ...

The working process and daily maintenance method of glass engraving machine

The glass engraving machine is a kind of CNC machine tool, which is mainly used in the fine processing and special-shaped cutting of various ultra-thin glass. With the development and demand of the electronic consumer market in the future, more ...

Analyze the different feeding methods of double-end grinder

The machining accuracy that can be achieved by the double-end surface grinder is the first choice for machining workpieces that require high parallelism, size, and surface roughness of the top and bottom of the machined parts. The big difference between ...

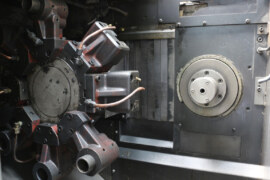

The advantages and precautions of the use of the two-jaw chuck for the rear pull oblique column

The two-jaw chuck of the back-drawn oblique column can upgrade the original equipment, optimize the traditional multi-clamping and multi-sequence processing mode to a single-clamping multi-sequence processing mode, improve the automation degree of the original equipment, and improve the processing accuracy ...

For the use of section steel cutting machines, users of these safety rules must remember to follow

The section steel cutting machine is a very powerful large-scale processing equipment, which can complete the cutting of the length of the section steel workpiece, the bevel of the web and wing plate, the wedge lock and the bolt hole ...

What problems should the machining center pay attention to when processing composite materials?

What problems should the machining center pay attention to when processing composite materials? In the processing of these composite materials, we have to process them according to the types of composite materials. Here is a brief introduction to some of ...

How to adjust the accuracy of CNC lathes is a very important thing

The CNC lathe is a precision lathe with high precision, high rigidity, high speed, high efficiency and high cost performance. Adopt horizontal flat guide rail structure, resin sand casting, good rigidity; guide rail quenching and fine grinding, precision and precision ...

What is the difference between precision stamping and ordinary stamping of CNC lathes

The precision stamping of a CNC lathe is essentially different from ordinary stamping. Precision stamping refers to various materials stamped out by a precision punching machine. These precision stamping parts themselves have higher precision requirements than ordinary stamping, such as ...

The Status Quo Of CNC Machine Tools In China And The Main Problems In The Development

In today’s world, industrially developed countries attach great importance to the machine tool industry, and are racing to develop advanced machine tools of mechatronics, high precision, high efficiency, and high automation in order to accelerate the development of industry and ...

The Essence Collection Of CNC Machining Programming Experience

The speed of the white steel knife should not be too fast. For coppersmiths, use white steel knives less frequently, and more use flying knives or alloy knives. When the workpiece is too high, you should use different length cutters ...

CNC Machining And Flexible Manufacturing

In 1946, the University of Pennsylvania in the United States successfully developed the world’s first electronic computer, which provided humans with tools that could enhance and partially replace mental labor, laying the foundation for the evolution of human society into ...

12 Experience Summaries Of CNC Machining

Due to the complexity of CNC machining (such as different machine tools, different materials, different tools, different cutting methods, different parameter settings, etc.), it is determined that CNC machining (whether machining or programming) reaches a certain level. It must take ...

Some Knowledge About The Use Of CNC Machining Carbide Tools

In addition to end mills and some end mills and cemented carbide as milling cutter materials for milling stainless steel, the other types of milling cutters are made of high-speed steel, especially tungsten-molybdenum series and high-vanadium high-speed steel, which have ...

Femtosecond Laser Technology For Medical Used

As a laser manufacturing company, we are often asked questions related to femtosecond laser surgery in ophthalmology. These questions typically involve the safety and precision of the surgery and the role we play as laser equipment providers. Next, let me ...

Basic Definition Of A Multi-Axis Machine

Multi-axis machining is a manufacturing process in which tools can be moved in 4 or more ways or directions to create parts that require precision machining, providing innovative and efficient solutions for complex geometric parts. This article will take a ...

Why Are Some Metal Parts Produced By Forging Rather Than Other Machining Methods?

First of all, we have to clarify what are the main metal CNC machining methods in current industrial production. Generally speaking, metal CNC machining methods are mainly divided into 4 categories: Casting: Metal Casting is the heating and melting of ...

The Classification Knowledge Of CNC Machining

The Classification Of CNC Machine Tools There are many classification methods for CNC machine tools, which can be roughly classified according to the type of machine tool structure, control method, china cnc machining movement method, and machine tool processing method. ...

How To Control Vibration During Cutting During CNC Machining?

Cutting Vibration How To Control Vibration During Cutting During CNC Machining?Cutting vibration usually occurs in turning of slender shafts, turning of thin-walled parts, etc. Once the vibration intensifies, there will be intense vibration with an amplitude exceeding several tens of ...