The machining accuracy that can be achieved by the double-end surface grinder is the first choice for machining workpieces that require high parallelism, size, and surface roughness of the top and bottom of the machined parts. The big difference between ...

Discy Latest Articles

The advantages and precautions of the use of the two-jaw chuck for the rear pull oblique column

The two-jaw chuck of the back-drawn oblique column can upgrade the original equipment, optimize the traditional multi-clamping and multi-sequence processing mode to a single-clamping multi-sequence processing mode, improve the automation degree of the original equipment, and improve the processing accuracy ...

For the use of section steel cutting machines, users of these safety rules must remember to follow

The section steel cutting machine is a very powerful large-scale processing equipment, which can complete the cutting of the length of the section steel workpiece, the bevel of the web and wing plate, the wedge lock and the bolt hole ...

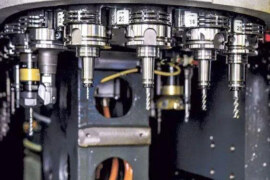

What problems should the machining center pay attention to when processing composite materials?

What problems should the machining center pay attention to when processing composite materials? In the processing of these composite materials, we have to process them according to the types of composite materials. Here is a brief introduction to some of ...

How to adjust the accuracy of CNC lathes is a very important thing

The CNC lathe is a precision lathe with high precision, high rigidity, high speed, high efficiency and high cost performance. Adopt horizontal flat guide rail structure, resin sand casting, good rigidity; guide rail quenching and fine grinding, precision and precision ...

What is the difference between precision stamping and ordinary stamping of CNC lathes

The precision stamping of a CNC lathe is essentially different from ordinary stamping. Precision stamping refers to various materials stamped out by a precision punching machine. These precision stamping parts themselves have higher precision requirements than ordinary stamping, such as ...

The Status Quo Of CNC Machine Tools In China And The Main Problems In The Development

In today’s world, industrially developed countries attach great importance to the machine tool industry, and are racing to develop advanced machine tools of mechatronics, high precision, high efficiency, and high automation in order to accelerate the development of industry and ...

The Essence Collection Of CNC Machining Programming Experience

The speed of the white steel knife should not be too fast. For coppersmiths, use white steel knives less frequently, and more use flying knives or alloy knives. When the workpiece is too high, you should use different length cutters ...

CNC Machining And Flexible Manufacturing

In 1946, the University of Pennsylvania in the United States successfully developed the world’s first electronic computer, which provided humans with tools that could enhance and partially replace mental labor, laying the foundation for the evolution of human society into ...

12 Experience Summaries Of CNC Machining

Due to the complexity of CNC machining (such as different machine tools, different materials, different tools, different cutting methods, different parameter settings, etc.), it is determined that CNC machining (whether machining or programming) reaches a certain level. It must take ...