As a laser manufacturing company, we are often asked questions related to femtosecond laser surgery in ophthalmology. These questions typically involve the safety and precision of the surgery and the role we play as laser equipment providers. Next, let me ...

Discy Latest Articles

Basic Definition Of A Multi-Axis Machine

Multi-axis machining is a manufacturing process in which tools can be moved in 4 or more ways or directions to create parts that require precision machining, providing innovative and efficient solutions for complex geometric parts. This article will take a ...

Why Are Some Metal Parts Produced By Forging Rather Than Other Machining Methods?

First of all, we have to clarify what are the main metal CNC machining methods in current industrial production. Generally speaking, metal CNC machining methods are mainly divided into 4 categories: Casting: Metal Casting is the heating and melting of ...

The Classification Knowledge Of CNC Machining

The Classification Of CNC Machine Tools There are many classification methods for CNC machine tools, which can be roughly classified according to the type of machine tool structure, control method, china cnc machining movement method, and machine tool processing method. ...

How To Control Vibration During Cutting During CNC Machining?

Cutting Vibration How To Control Vibration During Cutting During CNC Machining?Cutting vibration usually occurs in turning of slender shafts, turning of thin-walled parts, etc. Once the vibration intensifies, there will be intense vibration with an amplitude exceeding several tens of ...

The Most Complete CNC Machining Experience, Explained Step By Step From Easy To Difficult

General Rule Of Knife Path Rough opening: Under the maximum load of the machine tool, in most cases, the largest possible knife, the largest possible feed amount, and the fastest possible feed should be used. In the case of the ...

Process drawing design of 8000mm forging

The 8000mm extra large tubesheet metal forging has large diameter and heavy weight, which exceeds the production capacity of 185mn oil press. It is very difficult to adopt integral forming, so it can only be formed in sections. In the ...

Do you know the advantages and disadvantages of these resin 3D printers

There are still great differences between operating fdm3d printer and operating resin 3D printer. One is to use wound filament as consumables and the other is to use liquid resin as consumables. With FDM printer, I believe novices can quickly ...

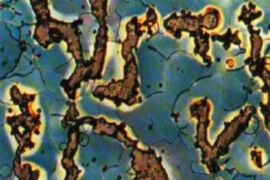

Three anti-corrosion treatment processes on the surface of aluminum profiles

In the production process of the aluminum profile frame, in addition to welding the various interface parts, it is also necessary to do anti-corrosion treatment to the entire material, so as to effectively prolong the use time of the entire ...

Causes of shape defects of stamping parts and debugging methods

Warpage (bending) The phenomenon that the stamped parts appear curved is called warpage (bend). The reason analysis and debugging methods are as follows; Due to the anisotropy of the material and the unleveling of the coil. It can be pressed ...