General Rule Of Knife Path

Rough opening: Under the maximum load of the machine tool, in most cases, the largest possible knife, the largest possible feed amount, and the fastest possible feed should be used. In the case of the same tool, the feed is inversely proportional to the feed amount. Under normal circumstances, the load of the machine tool is not a problem, and the principle of tool selection is mainly based on whether the two-dimensional angle and three-dimensional arc of the product are too small. After the tool is selected, the tool length is determined. The principle is that the tool length is greater than the machining depth. For large workpieces, it is necessary to consider whether the chuck interferes.

Smooth knife: The purpose of the smooth knife is to meet the precision cnc machining experience requirements of the surface finish of the workpiece and to reserve an appropriate allowance. Similarly, the light knife uses the largest knife and the fastest time possible, because the fine knife takes a long time, and the most suitable feed and feed are used. Under the same feed, the larger the lateral feed, the faster. The surface feed amount is related to the finish after machining, and the feed size is related to the surface shape of the surface. In the case of not damaging the surface, leave the minimum allowance, Use the largest knife, the fastest speed, and the appropriate feed.

Clamping Method

- 1. All clamps are horizontal and vertical.

- 2. Vise clamping: the clamping height should not be less than 10 mm, and the clamping height and cnc machining height must be specified when cnc machining metal parts. The cnc machining height should be about 5 mm higher than the plane of the vise, the purpose is to ensure the firmness, and at the same time not to hurt the vise. This kind of clamping is a general clamping, and the clamping height is also related to the size of the workpiece. The larger the workpiece, the larger the clamping height.

- 3. Clamping of the splint: the splint is coded on the worktable with a code, and the workpiece is locked on the splint with a screw. This kind of clamping is suitable for workpieces with insufficient clamping height and large cnc machining force. Generally, medium and large workpieces have better effect. .

- 4. Code iron clamping: when the workpiece is large, the clamping height is not enough, and it is not allowed to lock the wire at the bottom, the code iron is used for clamping. This kind of clamping requires a second clamping, first code the four corners, process the other parts, and then code the four sides and process the four corners. When the second clamping, do not let the workpiece loose, first code and then loose. You can also code both sides first and process the other sides.

- 5. Clamping of tools: if the diameter is above 10mm, the clamping length should not be less than 30mm; if the diameter is below 10mm, the clamping length should not be less than 20mm. The clamping of the tool should be firm, and the collision of the tool and the direct insertion of the workpiece should be strictly avoided.

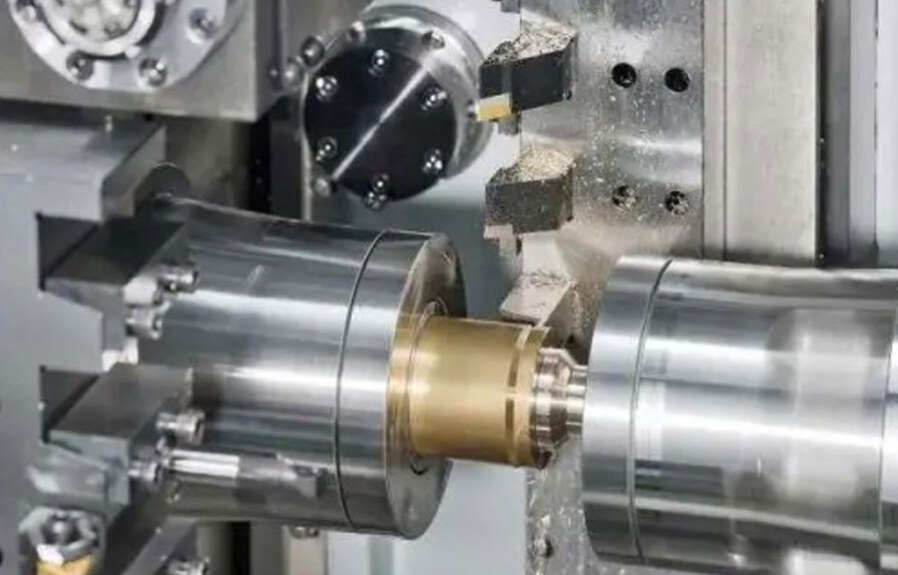

Classification Of Tools And Their Scope Of Application

1. According to the material

- White steel knife: easy to wear and tear, used for roughing copper and small steel materials.

- Tungsten steel knife: used for cleaning corners (especially steel) and light knives.

- Alloy knife: similar to tungsten steel knife.

- Purple knife; used for high-speed cutting, not easy to wear.

2. According to the cutter head

- Flat-bed knife: used for flat and straight sides to clear flat angles.

- Ball knife: used for light and light knives on various curved surfaces.

- Bull nose knife (with one side, two sides and five sides): used for roughing steel (R0.8, R0.3, R0.5, R0.4). Rough leather knife: used for rough cutting, pay attention to the allowance of the margin (0.3).

3. According to the cutter bar

- Straight bar knife: Straight bar knife is suitable for various occasions.

- Oblique bar knife: but not suitable for straight face and face with a slope less than the slope of the bar.

4. According to the blade

Two-blade, three-blade, four-blade, the more blades, the better the effect.

5. The difference between ball knife and flying knife light knife

Ball knife: When the concave ruler is smaller than the ball ruler, and the plane ruler is smaller than the ball R, the light will not reach (the bottom corner cannot be cleared).

Flying knife: The advantage is that it can clear the bottom corner. Comparison of the same parameters: V=R*ω, the speed is much faster (flying knife), the light is bright, and the flying knife is mostly used for the contour shape, and sometimes the flying knife does not need medium light. The disadvantage is that the size of the concave surface and the plane ruler are smaller than the diameter of the flying knife.

CNC With EDM, The Practice Of Copper

1. Under what circumstances do you need to be a copper worker:

The knife does not go down at all to make a copper male, and there is still a copper male that cannot go down. The shape is protruding and needs to be divided.

The knife can go down, but the knife that is easy to break also needs to be made of copper, which depends on the actual situation.

Products that require fire patterns need to be made of copper. If the copper male cannot be made, the bone position is too thin and too high, and the male is easily damaged and deformed. It is deformed during cnc machining and sparks. At this time, inserts are required.

The surface of things processed by Tong Gong (especially the curved surface will be very smooth and uniform) can overcome many problems in fine gongs and many problems in drawing. When a precise shape or a large margin is required, a thick copper male must be made.

2. Tong Gong’s practice:

Select the surface to be the copper male, complete the supplemented surface, or extend the extended surface to ensure that all the edges of the copper male are larger than the edges to be punched and do not damage the surface of other products, and remove unnecessary cleaning. The plane angle (the intersection with the plane angle is a deeper glue position), and make up a regular shape; find the maximum shape of the copper male, use a boundary and then project it to the support surface; determine the size of the reference frame, cut off the support surface, and reach This copper public drawing is basically completed; material preparation: length * width * height, length and width ≥ Ymax and Xmax as the reference frame, the length and width of the actual copper material must be larger than the reference frame on the picture. Height ≥ theoretical size of copper male + reference frame height + clamping height.

The Problem Of The Number Of Drawings

- If there is no ready-made cnc milling surface, the plane is divided into four sides, the center is to the origin, the top is zero, and the top surface is uneven (for copper males) to leave a margin of 0.1, that is, when the number is touched, the actual value of 0 (z ), which is 0.1 lower on the graph.

- When there is a ready-made processing surface, make the ready-made face on the figure 0(z), and the plane can be divided into the middle, otherwise, the actual height, width and , the length is different from the drawing, and it is programmed according to the actual material. In general, it is first processed to the size on the drawing and then processed to the shape on the drawing.

- When multiple positions are required for processing, the first position (standard position), the benchmarks of the other positions must be set well, and the length, width and height must be

- The positioning of the inserts: put them in the whole, raise the bottom to a certain height, and then raise the height of the drawing. The plane is divided according to the whole, and the height is locked with screws under the drawing; The center can be divided into the middle; the rough point can be divided into the maximum shape; cut a fixture, according to the fixture, the relative position of the insert drawing and the fixture is determined, and then the origin of the drawing is placed at the center of the fixture.

The Choice Of Rough Cutting Path

1. Surface grooving

The key is the selection of the range and the selection of the face.

The area of toolpath processing is: the selected surface within the selected range is the end surface, and the principle is all the places the tool can go from the highest point to the lowest point. The selected surface is preferably the whole surface, and the boundary can only be the area to be processed. The non-surface extends a distance of less than half the tool radius. Because there is enough margin for other surfaces, it is automatically protected; it is best to extend the lowest line, because There is an R gong at the lowest point.

Knife selection: If the tool cannot be fed spirally or obliquely, or the area that cannot be machined cannot be fed, the area where the tool cannot be fed is sealed and left for the second roughing.

Before the light knife, be sure to roughen all the areas that have not been roughened, especially the small corners, including two-dimensional corners, three-dimensional corners and sealed areas, otherwise the knife will be broken. Secondary roughing: generally use three-dimensional grooving to select the range, flat-bottomed knives, and those that can use plane grooving and contour tool paths. In the case of not hurting other surfaces, the center of the tool reaches the selected boundary. Generally, the boundary is not refined. Use a fast two-way angle depending on the situation. Helical feed, angle 1.5 degrees, height 1. The spiral lower knife is fed with an oblique line. Generally, the filter is turned on, especially when the curved surface is thickened.

- Retraction: Generally, relative retraction is not required, but absolute retraction is used. When there is no island, relative retraction is used.

- Plane grooving: milling various planes, concave and flat grooves, when milling part of an open plane, it is necessary to set the boundary, in principle, the tool can be fed (more than one tool diameter), the opening is more than half the tool diameter outside, closed peripheral.

- Shape: When the selected plane is suitable for shape layering, use the shape layered knife (plane shape), when the point of lifting the knife and the point of the lower knife are at one point, the knife does not need to be lifted. ; The correction direction is generally right correction (smooth knife).

- The tool path setting for mechanical correction: the correction number is 21, and the computer correction is changed to mechanical correction, and the feed is vertical feed. If the knife cannot pass, change the R to a larger value without leaving a margin.

- Equal height shape: it is suitable for the closed surface. If the open surface is four circles, the surface should be sealed. If it is within four circles or non-four circles, the range and height should be selected (a certain arc-shaped feed and thickening are required.) ), used for roughing: the machining distance in any plane is less than one tool diameter, if it is greater than one tool diameter, a larger tool or two contours of equal height should be used.

- Curved surface streamline: It has the best uniformity and brittleness, and it is suitable for light knives to replace contour shapes in many cases.

- Radial tool path: suitable for cases with large holes in the middle (use less). Matters needing attention: bounce the knife, the knife is not sharp, the knife is too long, when the workpiece is too deep, it should go around and cannot go up and down; the surfaces on both sides of the sharp corner in the workpiece should be divided into two tool paths, and cannot be crossed. The edge of the light knife is the best Extend (advance and retreat with an arc).

Clear Angle

- The clean angle here is the two-dimensional dead angle, which is the part that has not been reached in the previous process. If the light knife needs to go to the place, the angle should be cleaned first and then the light knife. If the angle is too small and deep, it can be divided into several knives. , do not use a knife to clear too many places.

- Clear three-dimensional corners: open some small grooves and some three-dimensional corners.

- The knife that is easy to break must be considered such as thin knife, too long, and excessive aluminum cnc machining volume (mainly z-direction, depth direction).

- Tool path: Use two-dimensional shape to walk, only small corners (R0.8) and two-dimensional plane angles can be cleared; use parallel tool paths; use contours of equal height; there is a kind of curved surface and shape that cannot be reached by the knife. Dead corners should be sealed first, and then the corners should be cleared. Small gaps in the large surface are generally sealed first.

Medium Light

- Medium light: Steel and fine materials as curved surfaces are medium light.

- Principle: There is a lot of allowance between layers when the knife is roughened. In order to obtain a better effect when the knife is polished,

- Features: fast removal, large knife flying knife, large feed, large spacing; no need to worry about the surface quality; flat workpieces do not need to be in the light; workpieces with the same height shape do not need the middle light, when the contour shape is thick, it can be a little thinner Putting the two processes together, the finer point refers to the surface allowance and the distance between layers; whether medium light is required, another important factor is the material of the work, the harder the material, the medium light is considered; the cnc machining of medium light The direction and the roughness of the light knife are best relative to the processing of such things will have a good effect and uniformity.

Light Knife

The light knife is to meet the assembly requirements of various products and molds, so it must be very careful, and different tool path settings and parameter settings are given according to different requirements.

- The lower and final height of the light knife are changed to 0. The tolerance design is within 1 wire, and no filtering is required (the smaller the workpiece, the smaller the tolerance, and the tolerance affects the appearance).

- The front mold and parting surface should achieve the best finish, the rear mold can be inferior, and other non-matching and vacant positions can be rough.

- The tool path design is determined by the following factors: specific shape (such as plane and other surfaces), steep surface and flat surface. Whether there is a sharp angle between the two sides (the sharp angle is separated). Whether the requirements of the two parts are different (whether or not to leave a margin, how much the margin is, and the requirements for the finish are different).

The problem of protecting the surface in the light knife is a big problem. The processed surface must be protected from errors during processing and protected according to the requirements of the protective surface. Range protection, 0 protection regardless of error, height range and plane range; protection surface protection. For the extension of the tool path, in the light knife, it is best to use an arc to advance and retract the tool when the tool path is processed to the edge, otherwise the surface is slightly extended in advance. Knife lift problem in Light Knife. Carrying knives is a waste of time, so try to avoid carrying knives.

- Method 1: Set the knife clearance (small gap)

- Method 2: Cover, seal the knife handle (small gap)

- Method 3: Avoid gaps (large gaps)

- Method 4: When the shape of the same height is extended to the feeding problem of the same height, the feeding of the first knife must be from the outside of the workpiece to avoid vibration and damage to the workpiece. All smooth knives must be equipped with feeding.

Tool wear problem: When the workpiece is large, multiple knives are required to finish the same repid prototyping parts.