The glass engraving machine is a kind of CNC machine tool, which is mainly used in the fine processing and special-shaped cutting of various ultra-thin glass. With the development and demand of the electronic consumer market in the future, more digital electronic display screens use glass as the display screen. Or touch screen, its market is getting bigger and bigger.

The glass has good light transmittance, abrasion-resistant surface after toughening, and has a good hand feeling. But its disadvantage is that it is fragile and easy to damage, and it is a big difficulty to realize the fine forming of glass. Therefore, the characteristics are as follows: the machine is small, the processing accuracy is high, the machine is stable, the finished product is fine, the processing speed is fast, and the production efficiency is high.

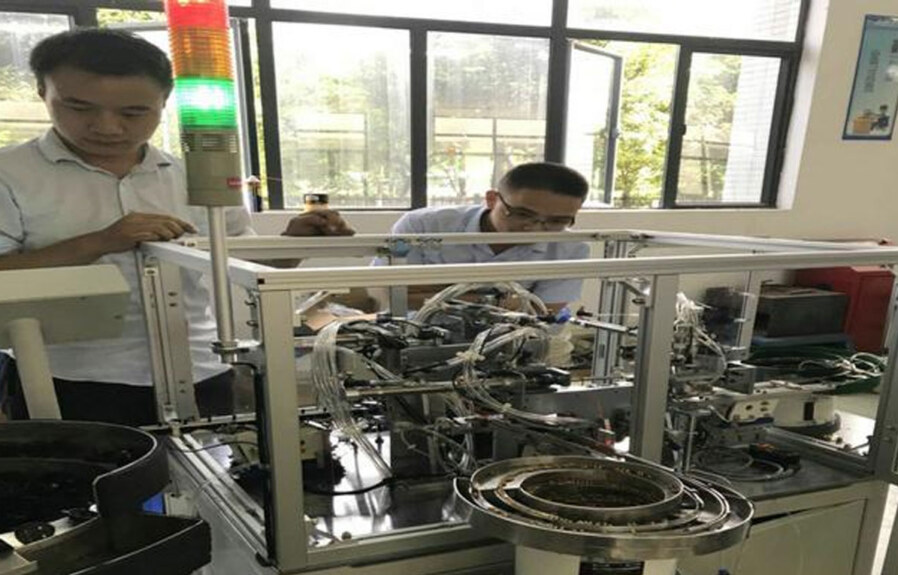

The working process of glass engraving machine is mainly composed of three parts:

- 1. Graph input is to process and organize the graphs to be carved into digital graph files that can be recognized by the computer through the engraving software, so as to control the processing machinery to work automatically.

- 2. Data processing is to use a computer to further process the graphics files processed and sorted out by the engraving software into electrical signals that can control the action of the processing machinery.

- 3, the processing process is automatically controlled, and computer instructions are executed to complete the graphic engraving processing. In the entire processing process, the operator is only responsible for inputting processing data, loading and unloading workpieces and monitoring the processing process, and other tasks are automatically completed by this equipment.

The following is the daily maintenance method of the glass engraving machine:

- 1. The continuous running time is less than 10 hours per day to ensure the cleanliness of the cooling water and the normal operation of the water pump. The water spindle motor must not be short of water. The cooling water should be replaced regularly to prevent the water temperature from being too high. If the working environment temperature is too low in winter, the water in the water tank can be replaced with antifreeze.

- 2. Every time the machine is used, pay attention to cleaning. Be sure to clean up the dust on the platform and transmission system, and lubricate the transmission system (X, Y, Z three axes) regularly (weekly). (Note: The X, Y, Z three-axis polished rods are maintained with oil; the screw part is added with high-speed butter; if the working environment temperature is too low in winter, the screw and polished rods (square rail or round rail) should be washed and cleaned with gasoline first , And then add oil, otherwise it will cause excessive resistance in the transmission part of the machine and cause the machine to displace.)

- 3. When performing maintenance and inspection on electrical appliances, be sure to cut off the power supply, wait until there is no display on the monitor and the main circuit power indicator light goes out before proceeding.