- 1. The thickness tolerance of stamping materials should comply with national standards: different mold gaps are suitable for materials of different thicknesses. If the thickness tolerance of the material is too large, it will not only directly affect the quality of the stamping parts, but also may cause damage to the mold or press.

- 2. The stamping material has high surface quality: the surface of the metal stamping material is clean and smooth, free of oxide scale, cracks, rust spots, scratches, delamination and other defects. The material with good surface condition is not easy to break during processing, and it is not easy to scratch the mold, and the surface quality of the obtained stamping parts is also good.

- 3. The stamping material should have good plasticity: the stamping material should have higher elongation and section shrinkage, lower yield and higher tensile strength, higher plasticity, and a large degree of deformation, which is conducive to The stability of the stamping process and the uniformity of deformation have improved the forming dimensional accuracy of precision stamping parts.

- 4. Stamping materials should have good adaptability for mechanical joining and further processing (such as welding, polishing, etc.), and should not damage mechanical equipment.

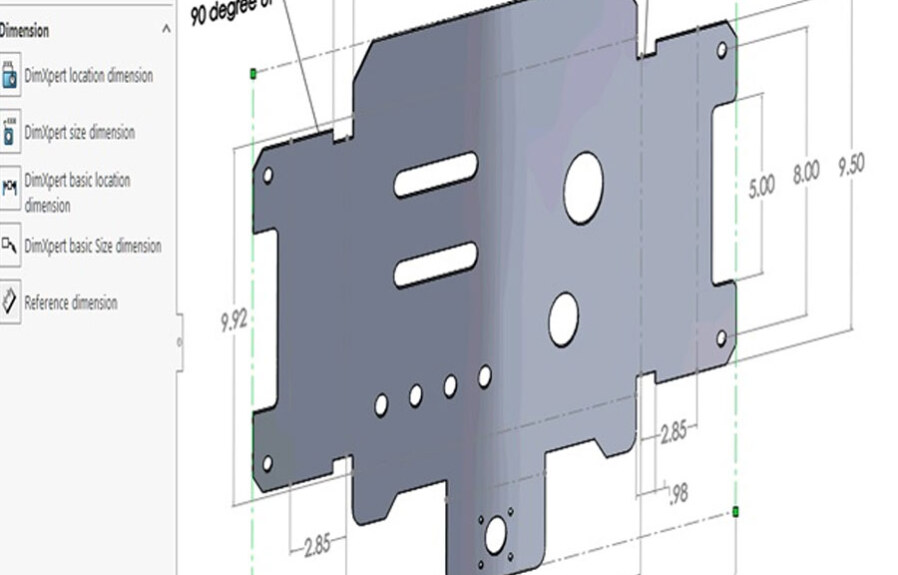

Process requirements that should be met by stamping materials for precision stamping parts

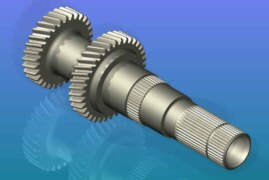

Cnc Operating