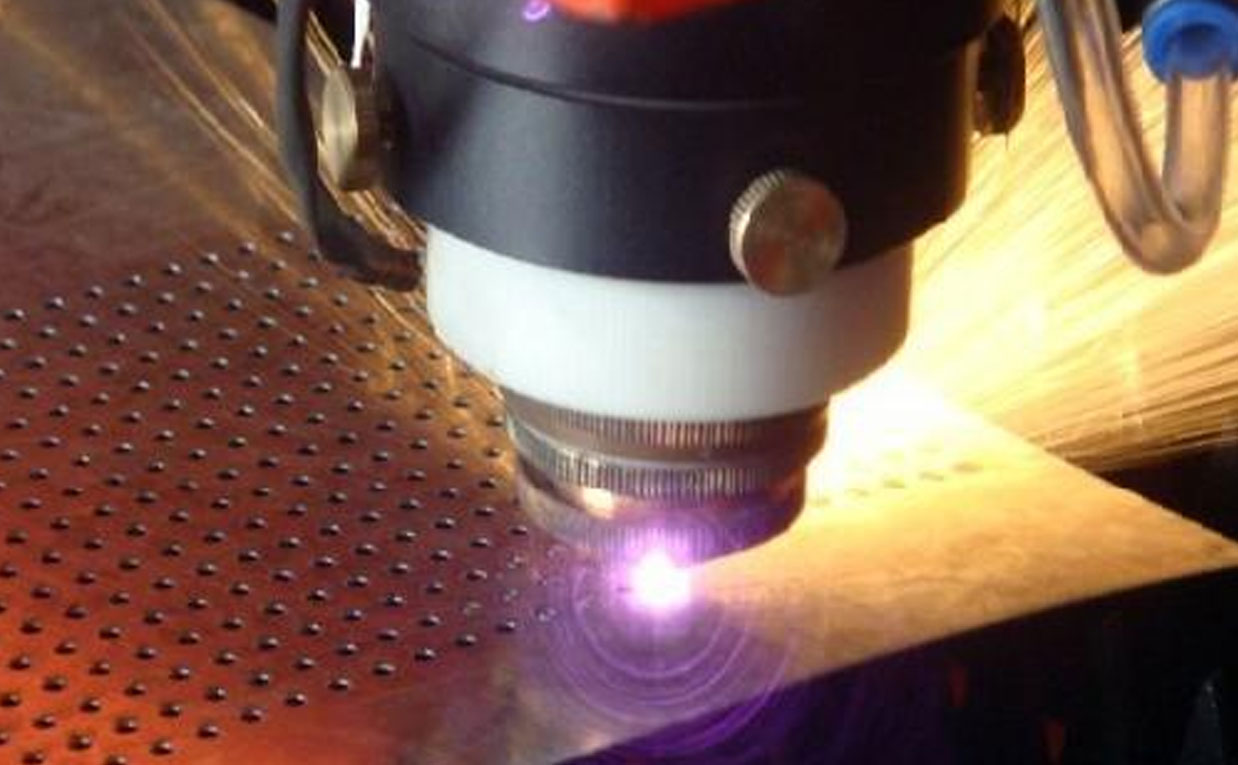

At present, the newly developed fiber laser cutting machine equipment has great practical advantages in use, and has gradually become a more popular cutting equipment in the current processing market. The cutting process is a very basic process in sheet metal processing. First, you must understand the optical fiber The working principle of the laser cutter is a device that converts electric energy into light energy by a laser, and then through a shearing device, the positive light is concentrated on the surface of the sheet to achieve a better use effect.

Due to the nature of the equipment, the fiber laser cutting machine belongs to the thermal cutting technology. Compared with the traditional cutting board, punching and other machines, it has many special effects with less deformation. Since the price of the equipment at the time of purchase is of concern to all customers, The price of fiber laser cutting machines with different powers is different, and the price of the same power configuration is also different. Under the same power and the same configuration, if the prices of different manufacturers are very different, you can further consult multiple manufacturers to carry out Understand that there are more small manufacturers nowadays, so users must carefully understand and choose.

Because of the actual after-sales service problems, it beneficially reflects the professionalism of fiber laser cutting machine manufacturers. Generally, powerful companies make improvements based on the equipment on the market, and usually set up after-sales offices in various regions to facilitate faster service For current customers, except for some electricity and consumables, the equipment has no other costs when used. Only one person needs to operate it. Whether it is mass production or small mass production, it can be well satisfied.

The newly developed and designed fiber laser cutting machine has a certain flexibility in the laser cutter. Compared with traditional processing tools, the workload of personnel is reduced, and the processing materials and thickness are very wide. The laser cutting speed is much faster than traditional equipment. Therefore, it reflects a more superior performance.