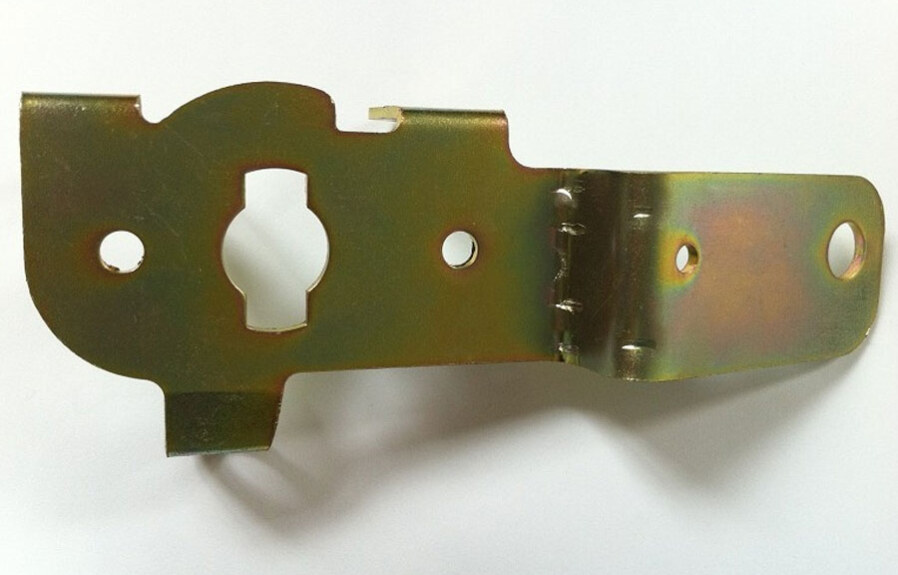

- 1. The cutting of the metal stamping parts is adapted to the contour of the local protrusion shape to make the material flow reasonably;

- 2. There should be enough laps between the cuts, so that the punch can tension the material, ensure the shape is clear, and avoid defects such as ripples, so that a good quality of the flanging hole can be obtained after trimming;

- 3, the cut part of the incision, that is, the opening part should be adjacent to the edge of the protruding part, or the area that is easy to rupture;

- 4. The number of cuts should ensure that the material at the protruding part is uniformly deformed, otherwise it may not be able to prevent ripples;

The principle of notch layout in stamping process

Cnc Operating