In addition to end mills and some end mills and cemented carbide as milling cutter materials for milling stainless steel, the other types of milling cutters are made of high-speed steel, especially tungsten-molybdenum series and high-vanadium high-speed steel, which have good results. The durability can be 1 to 2 times higher than that of W18Cr4V.

The spray cooling method has the most significant effect, which can increase the durability of the milling cutter by more than one time; if the general 10% emulsion is used for cooling, the cutting fluid flow should be ensured to achieve sufficient cooling. When the carbide milling cutter mills stainless steel, take Vc=70~150m/min and Vf=37.5~150mm/min. At the same time, make appropriate adjustments according to the alloy grades and workpiece materials.

Stainless steel has strong adhesion and fusion, and the chips easily adhere to the cutting edge of the milling cutter, which worsens the cutting conditions; when up-milling, the cutting edge slides on the hardened surface first, which increases the tendency of work hardening; impact during milling , The vibration is large, which makes the cutting edge of the milling cutter easy to chip and wear. When milling stainless steel, the cutting edge must be sharp and able to withstand impact, and the chip pocket must be large. Large helix angle milling cutters (cylindrical milling cutters, end milling cutters) can be used, and the helix angle b is increased from 20° to 45° (gn=5°), and the tool durability can be increased by more than 2 times, because the work of the milling cutter at this time The rake angle g0e is increased from 11° to more than 27°, and the milling is brisk. But the value of b should not be too large, especially for end mills with b≤35°, so as not to weaken the teeth.

Using wave-edge end mills to process stainless steel pipes or thin-walled parts, cutting is brisk, vibration is small, chips are fragile, and the workpiece is not deformed. High-speed milling with cemented carbide end mills and stainless steel with indexable end mills can achieve good results. Milling 1Cr18Ni9Ti with silver chip end mill, its geometric parameters are gf=5°, gp=15°, af=15°, ap=5°, kr=55°, k′r=35°, g01=-30° , Bg=0.4mm, re=6mm, when Vc=50~90m/min, Vf=630~750mm/min, a′p=2~6mm and the feed per tooth reaches 0.4~0.8mm, the milling force will be reduced 10% to 15% less, milling power is reduced by 44%, and efficiency is greatly improved. The principle is to grind a negative chamfer on the main cutting edge, and artificially generate a built-up edge during milling, so that it can replace the cutting edge for cutting. The rake angle gb of the built-up edge can reach 20 ~ 302, due to the main deflection angle As a result, the built-up edge is subjected to a thrust parallel to the cutting edge generated on a rake face and becomes a secondary chip flowing out, thereby taking away the cutting heat and reducing the cutting temperature. When milling stainless steel, down milling should be used as much as possible. The asymmetric down milling method can ensure that the cutting edge is smoothly cut away from the metal, and the chip bonding contact area is small, and it is easy to be thrown off under the action of high-speed centrifugal force, so as to avoid the impact of chips on the rake face when the cutter teeth re-cut into the workpiece The phenomenon of spalling and chipping improves the durability of the tool.

Carbide milling cutter milling method:

The feed direction of the carbide milling cutter relative to the workpiece and the rotation direction of the milling cutter mainly have the following two milling methods:

The first type is down milling. The rotation direction of the milling cutter is the same as the cutting feed direction. When the cutting starts, the milling cutter bites the workpiece and cuts off the final chips.

The second type is up milling. The rotation direction of the milling cutter is opposite to the cutting feed direction. The milling cutter must slide on the workpiece for a period of time before starting to cut, starting with the cutting thickness as zero, and reaching the cutting thickness at the end of the cutting maximum.

During down milling, the cutting force presses the work piece against the worktable, and during up milling, the cutting force pushes the work piece away from the worktable. Because the cutting effect of down milling is the best, down milling is usually the first choice. Only when the machine has thread clearance problems or problems that cannot be solved by down milling, then up milling is considered.

Every time the carbide milling cutter blade enters the cutting, the cutting edge must bear an impact load. The load depends on the cross section of the chip, the workpiece material and the cutting type. Under ideal conditions, the diameter of the milling cutter should be larger than the width of the workpiece.

The axis line of the milling cutter should always be slightly away from the center line of the workpiece. When the tool is placed directly at the cutting center, it is very easy to produce burrs. When the cutting edge enters and exits the cutting, the direction of the radial cutting force will change constantly, the machine tool spindle may vibrate and be damaged, the blade may be chipped and the machined surface will be very rough, the carbide milling cutter is slightly off-center, and the direction of the cutting force will change. No more fluctuations, the milling cutter will gain a preload.

Carbide milling cutter use:

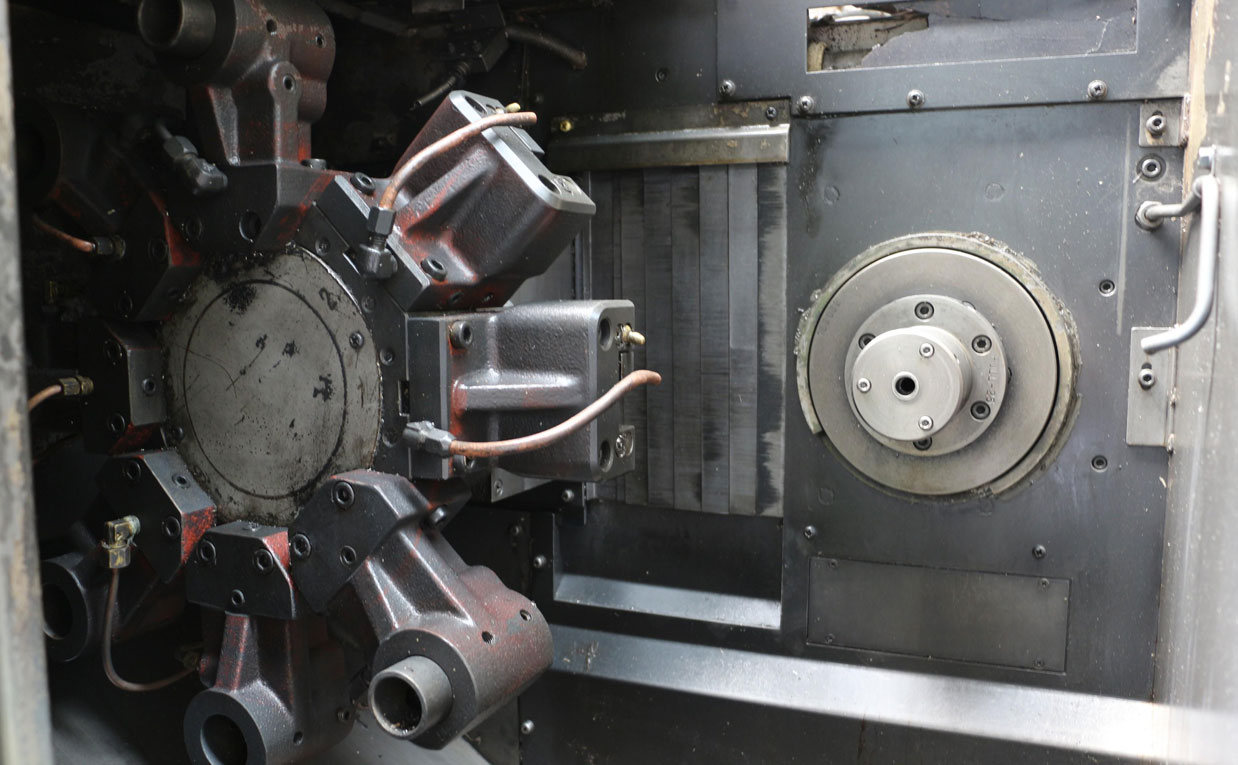

Carbide milling cutters are generally mainly used for CNC machining centers and CNC engraving machines. It can also be installed on an ordinary milling machine to process some harder and less complex heat-treated materials.

- 1. Carbide cylindrical milling cutter: used for processing planes on horizontal milling machines. The cutter teeth are distributed on the circumference of the milling cutter. According to the tooth shape, they are divided into straight teeth and spiral teeth. According to the number of teeth, there are two types: coarse and fine teeth. The helical coarse-tooth milling cutter has fewer teeth, high tooth strength and large chip space, suitable for rough machining; fine-tooth milling cutters are suitable for finishing.

- 2. Carbide face milling cutter: used for machining plane on vertical milling machine, end milling machine or gantry milling machine. There are cutter teeth on the end surface and circumference, as well as coarse and fine teeth. Its structure has three types: integral type, insert type and indexable type.

- 3. Carbide end mills: used for processing grooves and step surfaces, etc. The cutter teeth are on the circumference and end surfaces, and cannot be fed along the axial direction when working. When the end mill has end teeth passing through the center, it can feed axially.

- 4. Cemented carbide three-side and face milling cutter: used to process various grooves and step surfaces, with teeth on both sides and circumference.

- 5. Carbide angle milling cutter: It is used for milling grooves at a certain angle. There are two types of single-angle and double-angle cutters.

- 6. Carbide saw blade milling cutter: used to process deep grooves and cut off the workpiece, with more teeth on the circumference. In order to reduce the friction during milling, there are 15’~1° secondary deflection angles on both sides of the cutter teeth. In addition, there are keyway milling cutters, dovetail milling cutters, T-slot milling cutters and various forming milling cutters.

Carbide milling cutter maintenance

When the axis line of the cemented carbide milling cutter coincides with the edge line of the workpiece or is close to the edge line of the workpiece, the situation will be very serious. The operator should do the relevant equipment maintenance work:

- 1. Check the power and rigidity of the machine tool to ensure that the required milling cutter diameter can be used on the machine tool.

- 2. The overhang of the tool on the spindle is as short as possible to reduce the impact of the milling cutter axis and the position of the workpiece on the impact load.

- 3. Use the correct tooth pitch of the milling cutter suitable for the process to ensure that there are not too many blades meshing with the workpiece at the same time to cause vibration during cutting. On the other hand, ensure that there are enough blades when milling narrow workpieces or milling cavities. Engage with the workpiece.

- 4. Make sure to use the feed per blade so that the correct cutting effect can be obtained when the chip is thick enough to reduce tool wear. The indexable insert with positive rake angle groove shape is adopted to obtain a smooth cutting effect and the lowest power.

- 5. Select the diameter of the milling cutter suitable for the width of the workpiece.

- 6. Choose the correct entering angle.

- 7. Place the milling cutter correctly.

- 8. Use cutting fluid only when necessary.

- 9. Follow the tool maintenance and repair rules, and monitor tool wear.